Homogeneous Flooring

Description

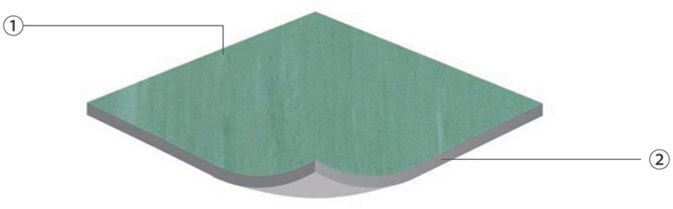

พื้นไวนิลแผ่นเนื้อเดียวกัน Prime Deco Homogeneous เป็นตัวเลือกแรกสำหรับพื้นที่ที่มีการใช้งานหนัก เช่น ระบบการศึกษา ระบบดูแลสุขภาพ ระบบธุรกิจ ระบบอุตสาหกรรม ระบบขนส่ง เป็นต้น เป็นพื้นพีวีซีรูปแบบหนึ่งที่ประกอบด้วย 2 ชั้น ชั้นการรักษาพื้นผิว PUR ทำให้ปลอดภัยและง่ายต่อการบำรุงรักษา ชั้นปูพื้นเนื้อเดียวกันอัดแน่นมีบทบาทสำคัญในด้านความยืดหยุ่น ความทนทาน และประสิทธิภาพสูง

พื้น Prime Deco Homogeneous มีสีและลวดลายหลากหลาย

PERFORMANCES AND BENEFITS

- ทนต่อการขัดถูได้ดีเยี่ยม

- พื้นผิวด้านด้าน ปรับปรุงการออกแบบและสีสัน

- มีจำหน่ายแบบแผ่น 2ม.

- พื้นไวนิลเนื้อเดียวกันเหมาะสำหรับพื้นที่การจราจรปานกลางถึงหนัก

- พื้นยืดหยุ่น ติดตั้งและเชื่อมได้ง่าย

- การออกแบบทิศทางมีอยู่ในการอ้างอิง 30 รายการ

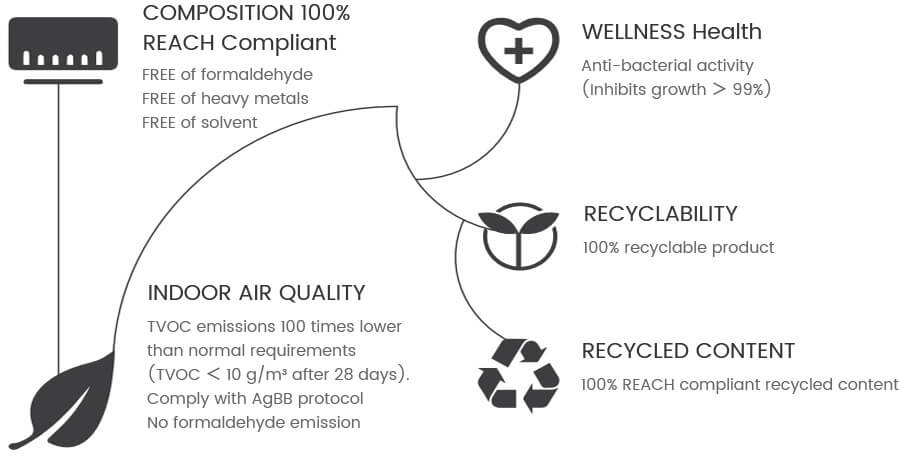

FEWER VOC`S, BETTER INDOOR AIR QUALITY

Description

เป็นวัสดุปูพื้นอัดแน่นเป็นเนื้อเดียวกันในแผ่น โดยมีการออกแบบที่ไม่เปลี่ยนทิศทาง สีย้อมเป็นส่วนผสมดิบเพื่อให้แน่ใจว่าสีสม่ำเสมอตลอดทั้งความหนาและพื้นผิวด้าน พื้นผิวถูกอัดแน่นเพื่อการสึกหรอที่ดีขึ้นและบำรุงรักษาง่าย

ได้รับการบำบัดด้วยการบำบัด PUR ซึ่งเป็นการปรับปรุงล่าสุดในการบำรุงรักษาพิเศษด้วยโพลียูรีเทนที่ได้จากการเชื่อมโยงข้ามด้วยเลเซอร์ UV การบำบัดด้วย PUR ช่วยหลีกเลี่ยงการเปื้อนสารเคมี เช่น เบตาดีน อีโอซิน หรือเจลล้างมือป้องกันแบคทีเรีย และเพิ่มความทนทานของพื้น ไม่มีแว็กซ์ตลอดชีวิต!

Prime Deco Homogeneous Flooring คอลเลกชันแบบไม่กำหนดทิศทางประกอบด้วยการกระทำของแบคทีเรียและเชื้อรา วัสดุปูพื้นเป็นไปตามมาตรฐาน EN 649 (34-43) และมีระดับการสึกหรอ Group T เหมาะสำหรับพื้นที่ที่มีการจราจรหนาแน่นมาก และมีจำหน่ายในพาเลทกว้าง 50 สีคลาสสิกและอินเทรนด์

- PUR ป้องกันการบำรุงรักษาเป็นพิเศษ

- บดอัดพื้นเป็นเนื้อเดียวกัน

-

- พื้นอเนกประสงค์ที่เป็นเนื้อเดียวกันและมีความยืดหยุ่นสูง

- PUR ป้องกันการบำรุงรักษาพิเศษบำรุงรักษาง่าย

- พื้นผิวอัดแน่นเพื่อการสึกหรอที่ดีขึ้นและบำรุงรักษาง่าย

- รวมคุณสมบัติแบคทีเรียและเชื้อรา

- การออกแบบโพลีโครมแบบทิศทาง มีให้เลือกหลากหลายสีร่วมสมัยถึง 35 สี

Colors

Technical Support

| ITEM | STANDARD | REQUIREMENT | Mercury | Venus | Saturn | Mars |

| SPECIFICATION | ||||||

| Total thickness | EN428 | mm | 2 | 2 | 2 | 2 |

| Weight | EN430 | g/m2 | 2850 | 2950 | 2850 | 2950 |

| Width/length of sheet | EN426 | m/m | 2/20 | 2/20 | 2/20 | 2/20 |

| CLASSIFICATION | ||||||

| European | EN649 | class | 34/43 | 34/43 | 34/43 | 34/43 |

| Fire rating | EN13501-1 | class | Bfl-slBfl sl | Bfl-sl | Bfl-sl | Bfl-sl |

| GB8624 2012 | Bfl-sl | Bfl-sl | Bfl-sl | GB8624 2012 | - | |

| Toxic testing | GB18586-2001 | - | Pass | Pass | Pass | Pass |

| Static electrical propensity | EN1815 | KV | <2 | <2 | <2 | <2 |

| Electrical resistance | EN1081 | Ω | 109-1010 | 109-1010 | 109-1010 | 109-1010 |

| Slip resistance dry | EN13893 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | |

| Slip resistance wet | DIN51130 | class | R9 | R9 | R9 | R9 |

| PERFORMANCE | ||||||

| Abrasion resistance | EN660.2 | mm3 | ≤4.0 | ≤4.0 | ≤4.0 | ≤4.0 |

| Abrasion group | EN649 | group | T | T | T | T |

| Dimensional stability | EN434 | % | ≤ 0.4 | ≤ 0.4 | ≤ 0.4 | ≤ 0.4 |

| Residual indentation | EN433 | mm | ≈ 0,03 | ≈ 0,03 | ≈ 0,03 | ≈ 0,03 |

| Castor chair test | EN425 | - | OK | OK | OK | OK |

| Thermal conductivity | EN12524 | w/(m.k) | ≈ 0.25 | ≈ 0.25 | ≈ 0.25 | ≈ 0.25 |

| Colour fastness | IS0105-B02 | degree | >6 | >6 | >6 | >6 |

| Chemical products resistance | EN423 | - | OK | OK | OK | OK |

| Anti-bacterial and fungicidal | - | - | OK | OK | OK | OK |

| Special maintenance treatment | - | μg/m3 | PUR Protect | PUR Protect | PUR Protect | PUR Protect |

| TVOC after 28 days | IS016000-6 | - | < 10 | < 10 | < 10 | < 10 |

| Colour number | - | - | 24 | 27 | 35 | 36 |

| CE MARKING | ||||||

| CE | EN14041 | - | ||||

Description

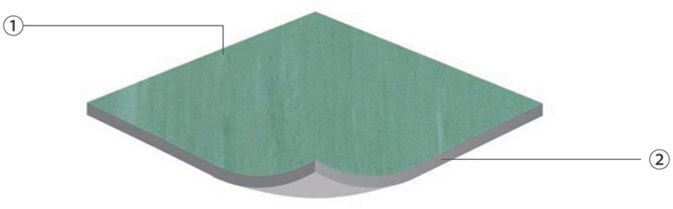

เป็นวัสดุปูพื้นแบบอัดอัดเนื้อเดียวกันในแผ่น โดยมีการออกแบบแบบไม่กำหนดทิศทาง โดยใช้สีย้อมเป็นส่วนผสมดิบเพื่อให้มั่นใจว่าสีจะสม่ำเสมอทั่วทั้งความหนาและพื้นผิวด้าน พื้นผิวถูกอัดแน่นเพื่อการสึกหรอที่ดีขึ้นและบำรุงรักษาง่าย

ได้รับการบำบัดด้วยการบำบัด PUR ซึ่งเป็นการปรับปรุงล่าสุดในการบำรุงรักษาพิเศษด้วยโพลียูรีเทนที่ได้จากการเชื่อมโยงข้ามด้วยเลเซอร์ UV การบำบัดด้วย PUR ช่วยหลีกเลี่ยงการเปื้อนสารเคมี เช่น เบตาดีน อีโอซิน หรือเจลล้างมือป้องกันแบคทีเรีย และเพิ่มความทนทานของพื้น ไม่มีแว็กซ์ตลอดชีวิต!

Prime Deco Homogeneous Flooring คอลเลกชันแบบไม่กำหนดทิศทางประกอบด้วยการกระทำของแบคทีเรียและเชื้อรา วัสดุปูพื้นเป็นไปตามมาตรฐาน EN 649 (34-43) และมีระดับการสึกหรอ Group T เหมาะสำหรับพื้นที่ที่มีการจราจรหนาแน่นมาก และมีจำหน่ายในพาเลทกว้าง 50 สีคลาสสิกและอินเทรนด์

- PUR ป้องกันการบำรุงรักษาเป็นพิเศษ

- บดอัดพื้นเป็นเนื้อเดียวกัน

-

- พื้นอเนกประสงค์ที่เป็นเนื้อเดียวกันและมีความยืดหยุ่นสูง

- PUR ป้องกันการบำรุงรักษาพิเศษบำรุงรักษาง่าย

- พื้นผิวอัดแน่นเพื่อการสึกหรอที่ดีขึ้นและบำรุงรักษาง่าย

- รวมคุณสมบัติแบคทีเรียและเชื้อรา

- การออกแบบโพลีโครมแบบทิศทาง มีให้เลือกหลากหลายสีร่วมสมัยถึง 35 สี

Colors

Technical Support

| ITEM | STANDARD | REQUIRMENT | Mercury | Venus | Saturn | Mars |

| SPECIFICATION | ||||||

| Total thickness | EN428 | mm | 2 | 2 | 2 | 2 |

| Weight | EN430 | g/m2 | 2850 | 2950 | 2850 | 2950 |

| Width/length of sheet | EN426 | m/m | 2/20 | 2/20 | 2/20 | 2/20 |

| CLASSIFICATION | ||||||

| European | EN649 | class | 34/43 | 34/43 | 34/43 | 34/43 |

| Fire rating | EN13501-1 | class | Bfl-slBfl sl | Bfl-sl | Bfl-sl | Bfl-sl |

| Fire rating | GB8624 2012 | - | Bfl-slBfl sl | Bfl-sl | Bfl-sl | Bfl-sl |

| Toxic testing | GB18586-2001 | - | Pass | Pass | Pass | Pass |

| Static electrical propensity | EN1815 | KV | <2 | <2 | <2 | <2 |

| Electrical resistance | EN1081 | Ω | 109-1010 | 109-1010 | 109-1010 | 109-1010 |

| Slip resistance dry | EN13893 | ≥0.3 | ≥0.3 | ≥0.3 | ≥0.3 | |

| Slip resistance wet | DIN51130 | class | R9 | R9 | R9 | R9 |

| PERFORMANCE | ||||||

| Abrasion resistance | EN660.2 | mm3 | ≤4.0 | ≤4.0 | ≤4.0 | ≤4.0 |

| Abrasion group | EN649 | group | T | T | T | T |

| Dimensional stability | EN434 | % | ≤ 0.4 | ≤ 0.4 | ≤ 0.4 | ≤ 0.4 |

| Residual indentation | EN433 | mm | ≈ 0,03 | ≈ 0,03 | ≈ 0,03 | ≈ 0,03 |

| Castor chair test | EN425 | - | OK | OK | OK | OK |

| Thermal conductivity | EN12524 | w/(m.k) | ≈ 0.25 | ≈ 0.25 | ≈ 0.25 | ≈ 0.25 |

| Colour fastness | IS0105-B02 | degree | >6 | >6 | >6 | >6 |

| Chemical products resistance | EN423 | - | OK | OK | OK | OK |

| Anti-bacterial and fungicidal | - | - | OK | OK | OK | OK |

| Special maintenance treatment | - | μg/m3 | PUR Protect | PUR Protect | PUR Protect | PUR Protect |

| TVOC after 28 days | IS016000-6 | - | < 10 | < 10 | < 10 | < 10 |

| Colour number | - | - | 24 | 27 | 35 | 36 |

| CE MARKING | ||||||

| CE | EN14041 | - | ||||